Add a 5 lb bag of custom roasted coffee to your parts order and get an extra 20% off our wholesale coffee prices!

Anti-suction Valve Shaft, Treated (B.2.013.01) (B.2.013)

This item ships directly from the manufacturer, and stock is not guaranteed. Lead time averaging 3 to 7 business days. If unavailable, the item will be backordered.

If you have any questions, please email or chat to confirm availability prior to ordering.

Restore the crucial safety and steam functionality of your commercial espresso machine with the genuine Anti-suction Valve Shaft, Treated (B.2.013.01) (B.2.013). This essential OEM component is the central moving part of the anti-suction valve (or vacuum breaker valve), a vital mechanism that prevents non-potable water from being drawn back into the boiler or main water supply—a critical requirement for health and safety compliance. Manufactured with a specialized treated coating (B.2.013.01) for superior resistance against scaling, corrosion, and high-temperature wear, this shaft ensures reliable, friction-free operation. Key features include precise threading and seating geometry designed for a perfect seal within the valve body, guaranteeing consistent venting of air when the boiler heats up.

A properly functioning anti-suction valve shaft is key to resolving common espresso machine problems. If you are experiencing issues like "my espresso machine boiler won't build pressure" or "why is my vacuum breaker valve leaking," a worn or scaled shaft is often the cause. Replacing this specific part eliminates sticking and leaking problems, ensuring your boiler can reliably vent false pressure and preventing water from spitting out when the machine is cooling down. This simple replacement restores system integrity, minimizes downtime in busy café environments, and maximizes the lifespan of your machine by protecting the boiler from vacuum-induced implosion.

Engineered to exacting specifications (Part B.2.013), this treated valve shaft is designed for a direct fit and easy replacement during routine preventative maintenance or when troubleshooting a faulty valve. Usage involves disassembling the existing anti-suction valve and installing this new shaft and associated seals. Investing in this OEM treated component is the definitive solution for maintaining consistent boiler performance, reducing the need for emergency repairs, and ensuring your commercial espresso operation runs smoothly and safely.

Descriptions are for reference only. We do our best to fill in the blanks when manufacturers don’t provide descriptions, but details can vary. We strongly recommend checking with the manufacturer for the exact part number you need. Ordering based on the part number—rather than the description—is the best way to ensure compatibility.

Compatible with:*

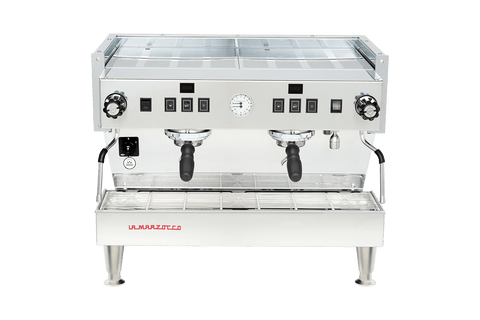

- FB70

- FB80

- GS3

- Linea Classic

- Strada MP

Categories:

*While we strive to ensure that all information on this site is accurate, we do not guarantee that the part compatibility listings are 100% correct. It is the responsibility of the purchaser to verify fitment for their specific machine before ordering.

Links to Machines | PDF Part Diagrams | Parts List